King Shing Group has over 20 years of rich experience in research and development, with a dedicated team of engineers focusing on the hardware and software system design of motors and electronic circuits. Our in-house capabilities enable us to directly design and manufacture products in terms of structure and processes, allowing us to transform optimized designs and ideas into tangible products according to our clients' needs.

We possess extensive expertise in the hardware and software system design of professional electronic circuits, including autonomous development of circuit design and electronic control fan drive programs. This expertise enables us to support various major car models with brushed and brushless DC fans, meeting the diverse needs of automotive cooling systems and various applications in the field of motors.

With years of accumulated experience and technological expertise in automotive motors and electronic products, we have the ability to rapidly integrate and tailor specifications to meet various product requirements. From design assessment, research, and development to complete autonomous integration in production, we can respond promptly, aiming to achieve high-quality, high-safety products. We aim to provide our customers with comprehensive, integrated solutions through a one-stop approach.

With years of experience and accumulated expertise in automotive electronic products, we possess rapid integration capabilities to tailor specifications that precisely meet various product requirements. With our complete autonomy in design evaluation, research and development, testing, and production, we can swiftly adapt to pursue high-quality and high-safety products, offering customized solutions for our customers.

Our laboratories boast an array of advanced testing equipment, including:

- 3D printers: used for rapid prototyping and quick experiments.

- Programmable constant humidity and temperature testing machines: employed to simulate product performance under various environmental conditions.

- Programmable high-temperature endurance testing machines: used to assess the durability of products operating in high-temperature environments.

- Tensile testing machines: utilized to evaluate the strength of connectors and components.

- Environmental temperature simulation testing machines: employed to simulate product performance under different temperature conditions.

- Automotive fan automated measurement systems: designed for testing and assessing automotive fan performance.

- Vibration testing equipment: simulates the vibration and load conditions of blades under different working conditions and tests their performance under these conditions.

- Sound testing equipment: used to evaluate product noise levels and soundproofing performance.

- Static pressure testing machines: employed to test product performance under various pressure conditions.

- Motor performance testing machines: used to assess motor performance.

- Motor endurance testing: employed to test motor durability.

- Motor torque testing: used to measure motor torque and efficiency.

- Salt spray testing machines: employed to assess the corrosion resistance of metals and other materials.

These testing facilities empower our research and development department to conduct comprehensive assessments of product performance during the development process, ensuring that our products meet the high standards of quality and reliability required by OEMs. Regardless of the type of testing your product requires, we can provide appropriate solutions.

Our goal is to guarantee that your products excel in real-world applications, capable of withstanding various challenges and environments. Our testing equipment and experience ensure that we can deliver high-quality assessments and assurances.

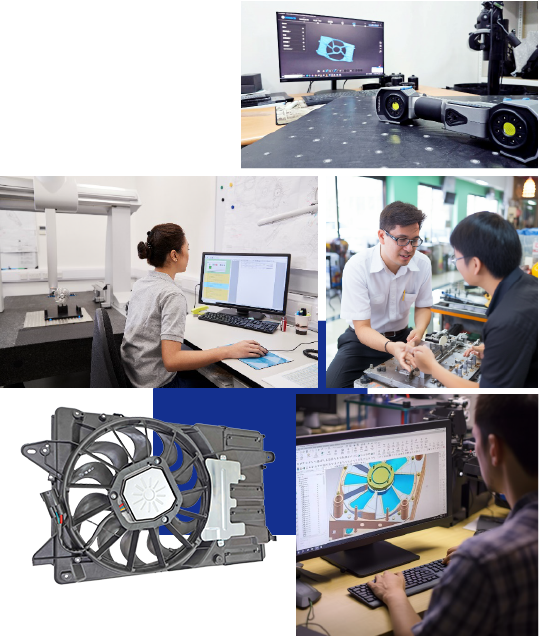

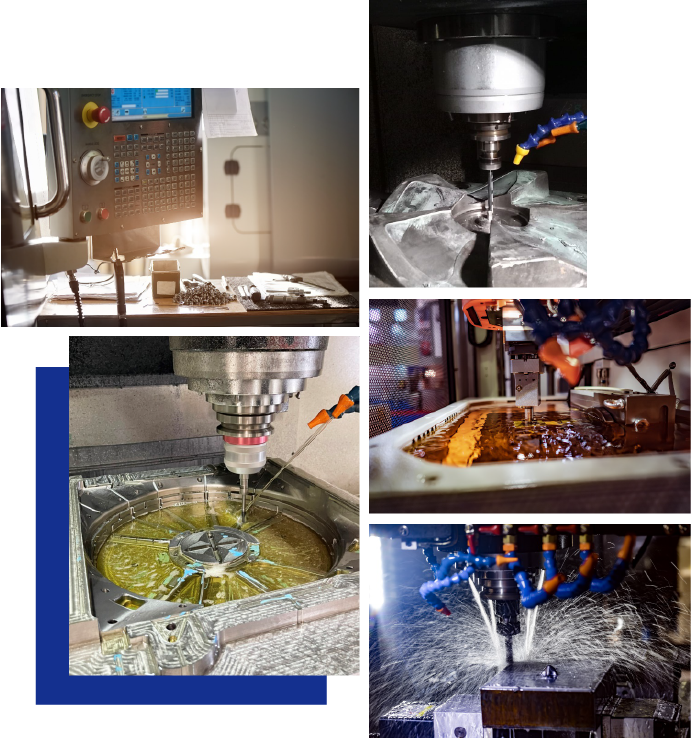

We have a team of professional mold designers, production experts, and mold specialists in Thailand who work closely with our clients to translate their concepts into reality, whether it be for plastic injection, stamping, or the production of various jigs and measuring fixtures. These designs and manufacturing processes are directly handled within our facility, allowing us to effectively shorten and control the development cycles and the timeliness of handling any anomalies. With our extensive experience in all these fields, we are well-prepared to lead projects from the initial idea to the final production stage.

Inside our In-House Mold and Tooling Shop, our proficient team manufactures an average of 10-12 precision molds, stamping dies, fixtures, and measurement tools every month. These molds, dies, fixtures, and tools undergo meticulous craftsmanship to adhere to the industry's highest standards. They find application in the manufacturing processes of our clients as well as within our own production facilities. This seamless integration ensures that our customers experience a smooth and efficient transition from design to production, resulting in top-quality products. Whether it's plastic injection molded components, stamped parts, or specialized fixtures and measurement tools, we deliver excellence across the board.

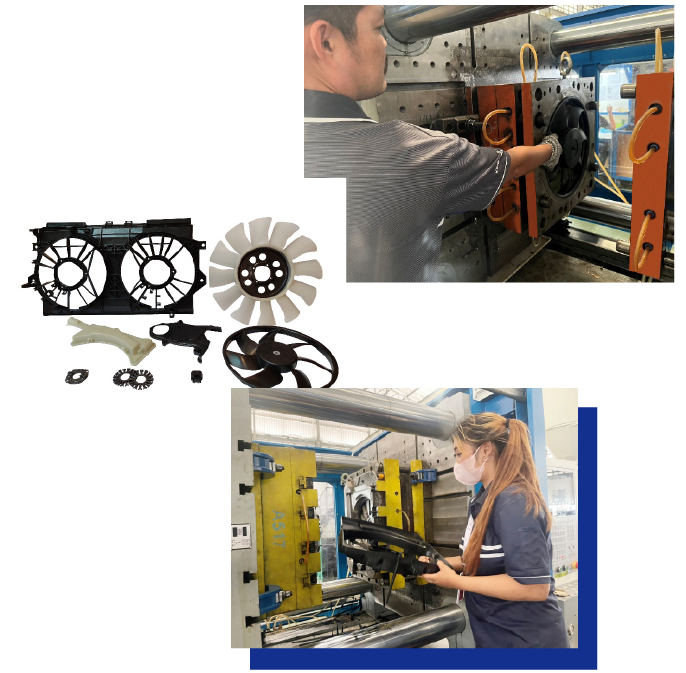

With over two decades of experience in the plastic injection molding industry, we possess a comprehensive range of both hardware and software equipment. Our equipment includes 33 injection molding machines, ranging from 45 to 800 tons in capacity. Currently, we work with a variety of materials, including PP, PA66, ABS, PPS, NYLON, and more.

We are committed to meeting our customers' needs and providing integrated, end-to-end services. Our services encompass mold development, design, sample production, quality inspection, data measurement, injection processing, and packaging, all the way through to delivery. We specialize in offering plastic injection services for both small and medium batch production, and we also provide OEM and assembly services.

Our highly experienced team is dedicated to delivering high-quality plastic injection molding solutions that meet our customers' specifications. Whether you require small-scale production or large-scale injection molding projects, we are equipped to provide dependable services to ensure that your products meet the highest standards.

Our manufacturing equipment includes:

Forty-one stamping machines with a tonnage range of 10-400 tons, are used to produce various components such

as terminals, automotive accessories, motor back covers, housings, iron shrouds, and iron blades.

Two high-speed stamping machines specially designed for the production of silicon steel stators used in

brushless motor rotors and DC motor rotors.

Two 400-ton high-speed stamping machines equipped with robotic arms capable of automated production, allowing

for the creation of 20 motor housings within just 1 minute.

For many years, we have been devoted to delivering professional ODM and OEM manufacturing services for high-precision, high-efficiency, and high-quality stamping parts, encompassing progressive dies and progressive stamping. Our unwavering commitment to excellence has garnered recognition and support from our valued customers. We consistently invest in our production capabilities to meet market demands and guarantee the provision of top-quality services.

We specialize in the production of high-precision motor shafts made from a variety of metals, offering comprehensive services that encompass turning and grinding. Our range of shafts includes diameters ranging from 4mm to 16mm, catering to both solid and hollow shaft requirements. What sets us apart is our collaborative approach – our R&D team collaborates closely with customers to co-design and enhance the shaft specifications, leveraging our extensive experience and expertise.

Our production facilities are equipped with state-of-the-art equipment, and our design proficiency can meet the demands of any shaft type. We take pride in delivering the highest level of service and ensuring excellent quality in every product we provide.

Automotive Wire Harness

We self-produce high-quality automotive Wiring Harness and plugs for Automotive Wire Assembly, Car Wire Harness, Motor Wire Harness, and Cable Assembly etc. All the cable and wire hardness comply with TUV, UL certified and ROHS regulations .

We can provide the overall solution with high quality and reasonable prices to meet the customer's needs according to their design and specifications.

We offer a wide range of paper boxes in various types and sizes to meet diverse packaging needs, including accepting small-quantity, diverse orders. Whether it's for product packaging or transportation, we can provide the best solutions. Additionally, we provide printing services, allowing us to print logos of any color and size according to our customers' requirements, helping their products stand out in the market. Our professional team ensures that your packaging is unique and adds value to your brand.